Biological Phosphorus Remove, Phos Bioremove

Background: Chemical such as Ca(OH)2 / FeSO4 / ALCL3 are widely use in phosphorus removal for wastewater treatment, However, the main problem of chemical phosphorus removal as following:

. High cost if long-term use

. Sludge volume increase 60%~100%

. Sludge concentration reduce 20%

Project information:

1) Project Site: Shanghai Techwell Biopharmaceutical Co., Ltd

2) Wastewater type: Pharmaceutical Wastewater

3) Flow rate: 100 m3 / d

4) Project problem: TP > 13 mg/L

5) Compliance regulation : TP < 5 mg/L

6) Flow diagram: Influent > EQ Tank > UASB > Anoxic > Aeration > SBR > Clarifier >Effluent

7) Tank size: UASB: 120 m3 ; Anoxic: 100 m3; Aeration: 100 m3 SBR: 450 m3*2

1) This customer always used chemical agents before to remove phosphorus, considering saving cost , hence specifically looking for biological phosphorus removal products.

2) What is PHOS REMOVE?

PHOS REMOVE is biological formulation by phosphorus-accumulating organisms, applied to activated sludge systems for the removal of phosphate. Bacteria count >2* 10^9 CFU/g;

3) How does PHOS REMOVE works?

The basic principle of biological phosphorus removal is to expose bacteria to alternating anaerobic and aerobic conditions to promote “luxury uptake” of phosphorus. Under anoxic to anaerobic conditions, phosphorus accumulating organisms (PAO) have the ability to take in organic substrate. In order to obtain the energy to incorporate the organic substrate into the microbial cell under anaerobic conditions, the bacteria releases phosphorus into the wastewater. When aerobic conditions are restored, the organic substrate taken in is converted to energy and cell mass. This allows the bacteria to take in phosphorus then needed to fulfill its nutrient needs.

4) What is benefit for PHOS REMOVE?

. Incorporates phosphorus into the sludge for ease of removal via WAS or Filtration

. Chemical addition savings

. Less sludge than chemical treat

. No need daily use, due to PAO reproductive capability

Project Implementation

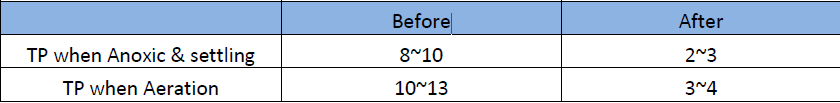

1) Day 1, dose 10 kg Phos Remove into SBR, TP rise from 13mg/L to 17 mg/L during anoxic & settling stage.

Because bacteria release phosphorus into the wastewater under anaerobic conditions. When aerobic conditions are restored, TP reduce from 17 mg/L to 8 mg/L .

2) Day 3, dose 5 kg Phos Remove into SBR, TP reduce from 10 mg/L to 2mg/L.

3) Day 5, dose 3 kg Phos Remove into SBR, TP reduce from 7 mg/L to 0.5 mg/L

4) After that, no more initial treatment dosing. Outlet TP maintain at average 3 mg/L

5) Maintenance dose 2.5 kg, twice per month. Monthly dose 5 kg only.