Old plant retrofit, Ammonia reduction, Nitrification Enhancement

1) Project : HuiChan Municipal wastewater treatment plant

2) Flow rate: 10,000 m3/ d

3) Flow diagram before retrofit: ABFT (Aeration biological fluidized tank)

4) Flow diagram after retrofit: A/O

5) Tank size: Anoxic tank 1,100 m3 (HRT 2.64 h) , Aeration tank 1,200 m3 (HRT 2.88 h)

6) Project problem: Old plant problem, NH3-N problem

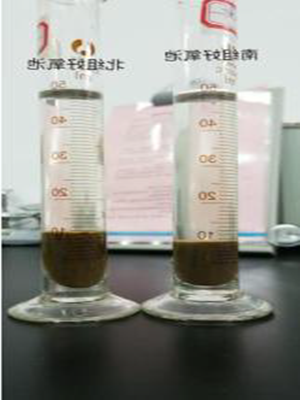

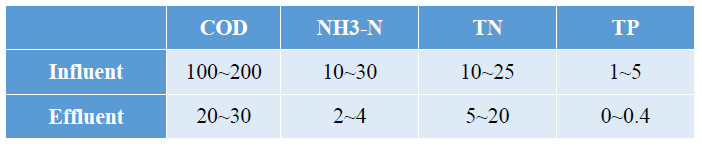

7) Influent analysis report:

1) PROBLEM: Due to ABFT process, Initial Round-shape carrier media density is 100 % full equipped in aeration tank, but after years operation, Biomass is serious lost because wear packing and density reduce to 50%, besides, lots of sludge deposited in pipeline, which lead to actual treatment capacity is only 20% of design.

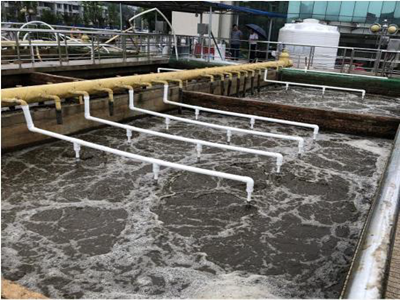

SOLUTION: Take out all media carrier, change to activated sludge process.

2) PROBLEM: Air diffuser pipeline detached and blocked caused by years disrepair, which lead to unevenness of aeration, and D.O in some place reach to 8~9 mg/L

SOLUTION: Repair the aeration pipe and maintain D.O at 4-5 mg/L evenly.

3) PROBLEM: Due to Inclined pipe packing in anoxic tank, and no any agitating and pushing device at inlet of anoxic tank, sludge deposit seriously at the inlet of anoxic tank.

SOLUTION: Install aeration device at inlet of anoxic tank, control the DO for dredge function, but does not affect the overall dissolved oxygen of the anoxic tank.

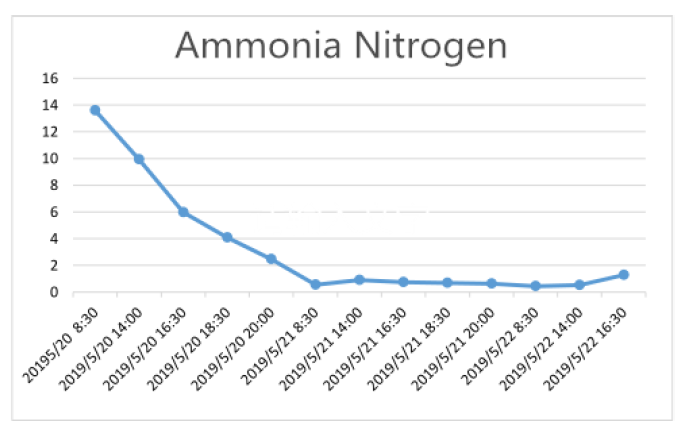

1) After retrofit plant and all carrier media take out, Stop flow in and out;

2) Add 15 ton dry sludge (moisture 80%) into aeration tank.

3) Dose 80 Liter nitrifying bacteria for cultivation.

4) Keep aeration until ammonia reduce to 2 mg/L.

5) Start to flow in, but slow increase from 160m3/h to 260 m3/h at first day.

6) On 2nd day, add another 15 ton dry sludge, and 50 liter nitrifying bacteria

7) Increase flow rate from 260 m3/h to 360 m3/h.

8) On 3rd day, add 30 liter nitrifying bacteria,

9) Increase flow rate from 360 m3/h to 420 m3/h, until system become stabilized.

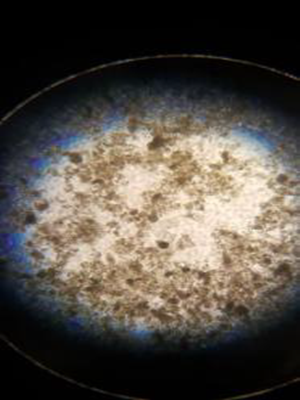

After 3 days of commissioning, the biochemical system gradually operated normally, and the activated sludge start to work. SV 30 result range at 20%.