Filamentous bulking, Ammonia reduction,

1) Project Site: Sinopec Jiujiang Plant

2) Wastewater type: Petroleum refinery wastewater

3) Flow rate: 200 ~300 m3 / hr

4) Project problem: Filamentous bulking and ammonia problem

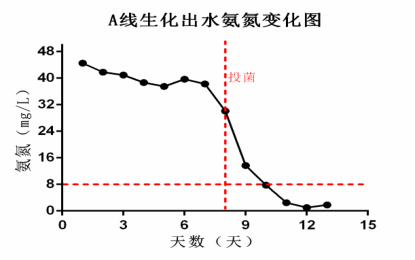

5) Desired goals: Control filamentous bulking and effluent ammonia within 8 mg/L

1) Flow diagram: Influent > EQ > Oil Separation > DAF > 1st A/O >

Clarifier >2nd A/O > 2nd Clarifier> BAF

2) Tank size:

1st A Tank 3873 m3 *2 ; 1st O Tank 6403 m3 *2

2nd O Tank 7200 m3; BAF tank 13000 m3

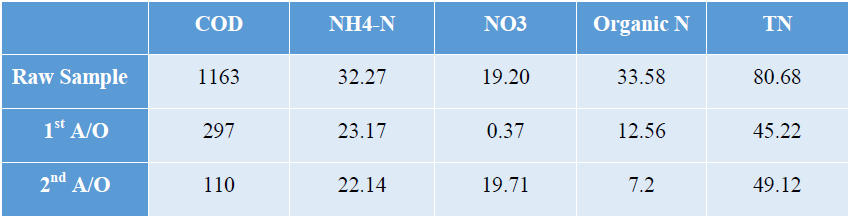

3) Wastwater analysis report:

1) Biological system was collapsed due to shock load such as sulfides, oils and organics amines. Suggest to inoculate bacteria to quick recovery.

2) Filamentous bulking, SV30 is 70%, loose zooglea and settles slowly. Suggest to discharge 20 % sludge and recultivate biomass.

3) Low nitrification performance (NH4-N problem) , suggest to inoculate nitrifying bacteria to control ammonia (NH4-N)

4) TN discharge violate local limit, and carbon source is insufficient, suggest to add methanol 300 Liter per day

1) Nitrifying bacteria : Control ammonia nitrogen and maintain discharge compliance

2) Anaerobic Bacteria: Quick recovery from filamentous bulking, improve settles problem

3) Hydrocarbon Bioremove: Special for petroleum refinery wastewater to reduce hydrocarbon

1) Check and make sure all facility, air diffuser, pipe, valve, instruments work properly.

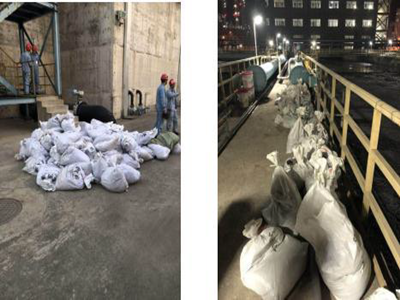

2) Discharge 20% sludge, add new sludge from municipal wwtp.

3) Add sodium hydroxide in fore-end pipeline before aeration tank, control PH at 7.5~8.5.

4) Add trisodium phosphate (TSP) in aeration tank, control TP at 2 mg/L.

5) Add methanol 300L/d to anaerobic tank.

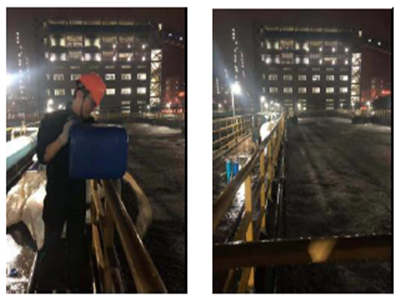

6) Continuously inoculate bacteria for 20 days.