petroleum industrial wastewater treatment,Ammonia removal, Hydrocarbon degradation

1) Project site: Shangdong SEIC Group;

2) Wastewater type: Petroleum refinery wastewater;

3) Flow rate: 2400 cmd/day

4) Flow diagram: EQ > O/W separator > DAF > Anoxic tank > Aeration tank >clarify tank>holding tank > BAF > Effluent

5) Tank size: 2 unit EQ tank 10,00 m3 each, 4 unit DAF 500 m3 each,

6 unit Anoxic tank 500 m3 each, total 3000 m3 (HRT 30 hrs)

12 unit Aeration tank 500 m3 each, total 6000 m3 (HRT 60 hrs)

1) The main pollutant of petroleum refinery wastewater contains hydrocarbon, hydrogen sulfide, ammonia compounds.

2) COD at 5000 mg/L, NH4-N at 160 mg/L, TP at 5 mg/L, pH at 7~8

3) The bioprocess was shockloaded by highly sulfide and oil substance influent, the nitrification rate was low, NH4-N almost no reduction.

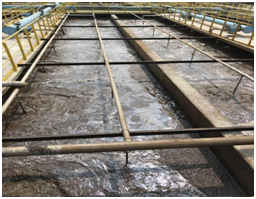

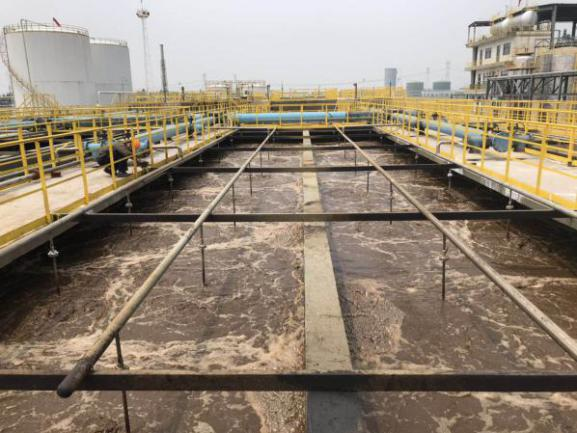

Pic. 1 Aeration tank Pic. 2 Sediment tank

1) Dose nitrifying bacteria to restart-up the nitrification process, nitrifying bacteria is a consortium of vigorous and specific microbes that when add to system,quickly increases the population to acceptable levels, and enables them to efficiently control the amount of ammonia present by oxidising it to nitrite and further breaking the nitrite down to nitrate.

2) Dose hydrocarbon bioremove to degrade oil in tank. Hydrocarbon Bioremove is a unique blend of different bacteria strains used to effectively degrade both aromatic and aliphatic hydrocarbons. Hydrocarbon Bioremove reinforces or augments the natural biological process.

Pic. 3 Nitrifying bacteria Pic. 4 Hydrocarbon Bioremove

1) Continuously daily dose nitrifying bacteria 60 kg for 10 days

2) Continuously daily dose hydrocarbon bioremove 30 kg for 10 days

3) Add Na2HPO4 and glucose to balance the nutrient.

4) Control the influent flow and don’t desludge during the cultivation period.

5) Monitor the NH4-N and CODcr, MLSS etc from outlet of anoxic, aeration, BAF

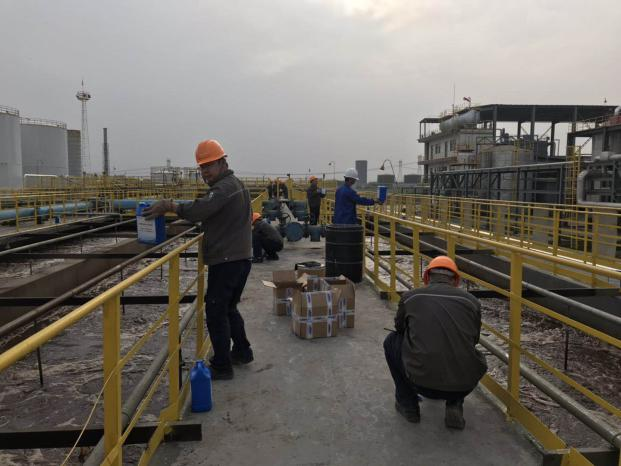

Pic. 5 Floating oil in aeration tank Pic. 6 Dosing bacteria

1) Floating oil was degraded by hydrocarbon bioremove in aeration tank, and release the toxic problem caused by that

Pic. 7 Floating oil before Pic. 8 Floating oil after

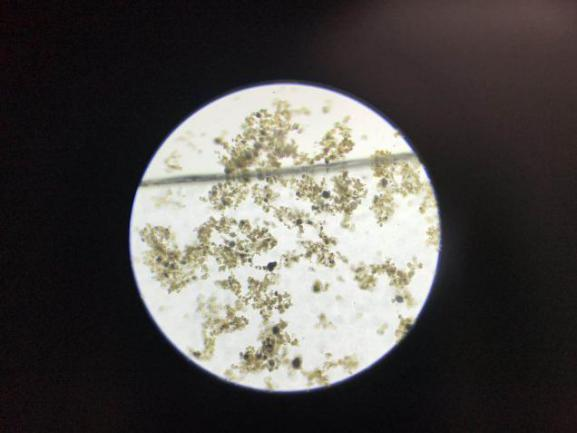

2) Microscop check result shows biomass become much compact than before

![]()

Pic. 9 Microscop check before Pic. 10 Microscop check after

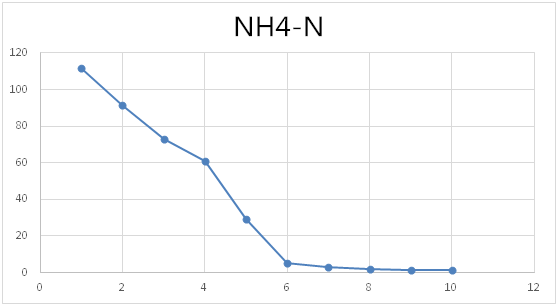

3) After dosing, NH4-N was significant decreased after 6 days, since then, the effluent NH4-N content is stable at about 1.5 mg/L.