WWTP Operation, Saving Cost

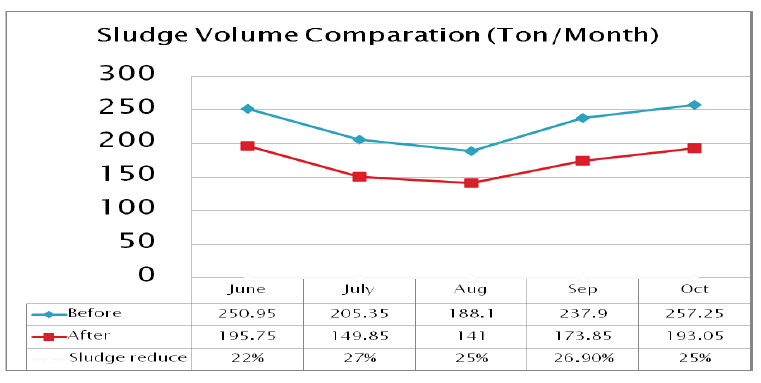

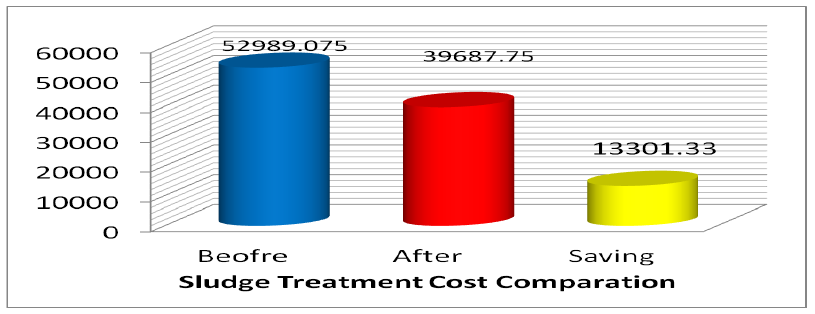

1) Sludge production reduced 25 % ;

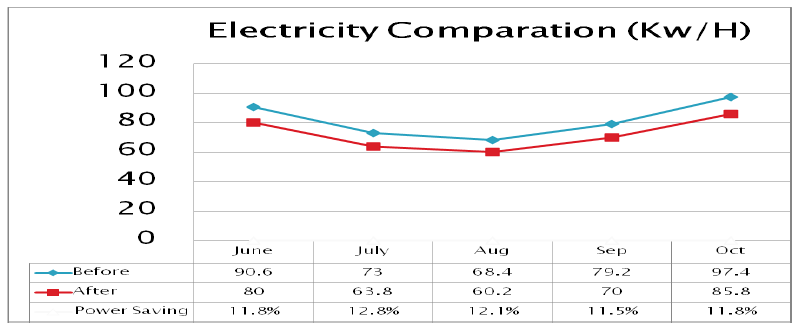

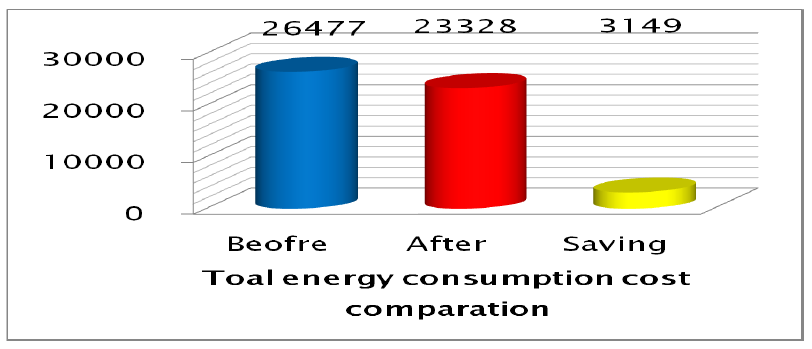

2) Electricity consumption reduced 12 %;

3) Increase diversity of biomass, treatment load reduced, improve anti shock load ability;

4) Significantly reduced odor during sludge treatment.

1) Plant flow rate: 10,000 m3/day,

2) Sludge volume 3,504 ton /year ( Water content 78%)

3) Wastewater process: Influent > Coarse Screen > Pump Lift > Fine Screens > Grit tank

> Primary Clarifier > AAO > Sedimental tank > Disinfecting tank > Efluent

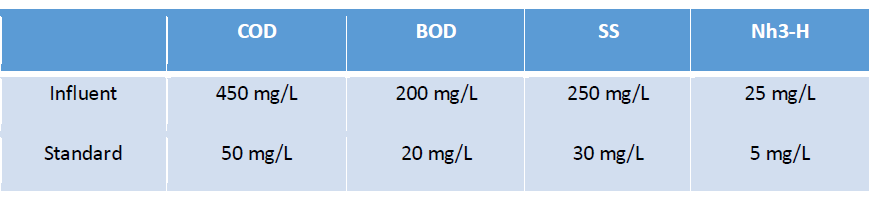

4) Wastewater Parameters

System Problem:

1) Reduce sludge treatment cost;

2) Energy saving, reduce daily operation cost;

3) Control odor around sewate plant;

Project Solution:

Continuously dosing AEROBIC BACTERIA 5 kg per day to aeration tank for 30 days